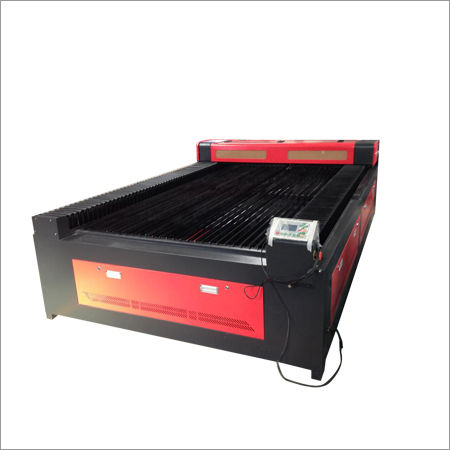

High Speed Laser Cutting Machine

High Speed Laser Cutting Machine Specification

- Phase

- Three Phase

- Working Area

- 1500 mm x 3000 mm

- Technology

- High-Speed Fiber Laser

- Power

- 1000W / 1500W / 2000W / optional

- Usage & Applications

- Metal Sheet Cutting, Industrial Fabrication, Automotive, Electrical Cabinet Manufacturing

- Product Type

- High Speed Laser Cutting Machine

- Laser Type

- Fiber Laser

- Material

- Cutting Thickness

- Up to 20 mm (depending on material and power)

- Cutting Area

- 1500 mm x 3000 mm

- Cutting Speed

- Max 80 m/min (material dependent)

- CNC Or Not

- Yes

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling Mode

- Water Cooling

- Control Software

- CypCut / FSCUT / Custom Compatible

- Graphic Format Supported

- AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

- Control System

- CNC Controller

- Voltage

- 380V / 50Hz / 60Hz

- Weight (kg)

- 3000 kg (approx)

- Dimension (L*W*H)

- 4500 mm x 2200 mm x 1800 mm

- Capacity

- Continuous Operation

- Feature

- High Precision, Low Maintenance, Fast Operation

- Color

- White/Blue/Custom

- Relative Humidity

- 80%, non-condensing

- Optical System

- Imported Lens and Mirrors

- Support Table

- Exchange Platform

- Drive System

- Dual Servo Motor Drive

- Positioning Accuracy

- 0.03 mm

- Safety Protection System

- Full Enclosure with Observation Window, Safety Sensors

- Operating Temperature

- 5C - 35C

- Noise Level

- 70 dB

- Auxiliary Gas

- Oxygen, Nitrogen, Air

- Optional Upgrades

- Dust Extraction System, Automatic Loading/Unloading, Camera Monitoring System

- Repeatability

- 0.02 mm

- Focus System

- Automatic Focusing Laser Head

- Interface

- Ethernet, USB

- Max Acceleration

- 1.5G

High Speed Laser Cutting Machine Trade Information

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- Delivery Time

- Week

- Certifications

- Yes

About High Speed Laser Cutting Machine

We are able to meet the varying needs of clients by providing optimum range of High Speed Laser Cutting Machine. Offered machine is highly appreciated due to its extraordinary speed and used for cutting the heavy workpiece at various industries like metalworking, woodworking, automotive etc. Manufacturing of provided machine is done by a team of dedicated professionals using contemporary technology. Furthermore, this High Speed Laser Cutting Machine can be availed from us at industry leading prices.

Keypoints:

- Excellent strength

- Smooth cutting edges

- Highly durable

- Simple operation

Superior Cutting Precision and Speed

Achieve unparalleled cutting accuracy with a 0.03 mm positioning tolerance and maximum acceleration of 1.5G. The high-speed fiber laser technology, dual servo drive system, and automatic focusing enable fast, consistent cuts at speeds up to 80 m/min, ideal for mass production and intricate industrial designs.

Advanced Safety and User Experience

Operator safety is prioritized with a fully enclosed structure, observation window, and integrated sensors. Optional upgrades like dust extraction and camera monitoring further enhance the operating environment, ensuring a safer, cleaner workspace while maintaining ease of use and high visibility.

Versatility Across Applications

This laser cutting machine processes a diverse range of metals, supporting automotive, electrical cabinet manufacturing, industrial fabrication, and more. Its compatibility with multiple graphics formats and control platforms simplifies integration into various production lines, optimizing workflow and productivity for manufacturers in India.

FAQs of High Speed Laser Cutting Machine:

Q: How does the high-speed laser cutting machine achieve such precise positioning and repeatability?

A: This machine utilizes dual servo motor drive and imported optical components, paired with an advanced CNC controller, to ensure each movement is carefully managed. The result is impressive positioning accuracy of 0.03 mm and repeatability of 0.02 mm, even at maximum acceleration speeds.Q: What materials and thicknesses can this laser cutting machine handle?

A: The system is designed for cutting stainless steel, carbon steel, aluminum, copper, brass, and other metals. Depending on the material and laser power selected (up to 2000W), it can effectively cut sheets up to 20 mm thick within a 1500 mm x 3000 mm area.Q: When should I consider optional upgrades like automatic loading or dust extraction?

A: Optional features such as automatic loading/unloading, dust extraction, and camera monitoring are particularly beneficial for high-volume, continuous operations. These upgrades streamline the process, reduce manual handling, and help maintain a clean, safe environment.Q: Where can this laser cutting machine be used effectively?

A: The machine excels in industrial fabrication, automotive manufacturing, electrical cabinet production, and any scenario involving metal sheet cutting. Its high precision and flexible support for various graphics formats make it ideal for manufacturers, importers, and service providers in India.Q: What is the process for operating the laser cutting machine, and which file formats are supported?

A: Operators can prepare designs in compatible graphic formats such as AI, PLT, DXF, BMP, Dst, Dwg, LAS, and DXP. The files are transferred to the machine via Ethernet or USB. The CNC-controller-driven process, supported by CypCut/FSCUT or custom software, manages cutting automatically according to the imported design.Q: How does the safety protection system ensure operator well-being?

A: The full enclosure with observation window, combined with safety sensors, ensures the operator is shielded from laser exposure and moving parts. The system constantly monitors for any anomalies, automatically stopping operation if unsafe conditions are detected.Q: What benefits does automatic focusing provide during operation?

A: Automatic focusing allows the laser head to quickly adjust to material thickness variations, ensuring optimal cutting quality throughout the operation. This improves production efficiency, reduces manual intervention, and ensures consistent results across diverse materials and jobs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machines Category

Large Bed Laser Cutting Machine

Laser Type : Other, CO2 Laser

Material : Other, Acrylic, MDF, Wood, Leather, Fabric, Paper, Plastic, etc.

MDF Laser Cutting Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Fabric Laser Cutting Machine

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Fiber Laser Metal Cutting Machine

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Laser Type : YAG

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry