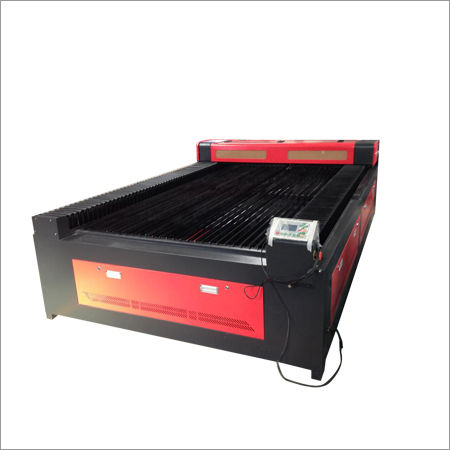

Large Bed Laser Cutting Machine

Large Bed Laser Cutting Machine Specification

- Working Area

- 1300 mm x 2500 mm

- Power

- Laser tube 100W/130W/150W/180W (optional)

- Phase

- Single/Three Phase

- Technology

- CO2 Laser Cutting

- Usage & Applications

- Industrial cutting of non-metal materials, sign making, furniture, template processing, advertising

- Product Type

- Large Bed Laser Cutting Machine

- Laser Type

- CO2 Laser

- Material

- Acrylic, MDF, Wood, Leather, Fabric, Paper, Plastic, etc.

- Cutting Thickness

- 0.5-25 mm (Material dependent)

- Cutting Area

- 1300 mm x 2500 mm

- Cutting Speed

- 0-600 mm/s

- CNC Or Not

- Yes

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling Mode

- Water Cooling

- Control Software

- RDWorks, LaserCut

- Graphic Format Supported

- AI, PLT, DXF, BMP, DST, DXP

- Control System

- DSP Control System

- Voltage

- 220V/380V, 50/60Hz

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 3550 mm x 2100 mm x 1150 mm

- Capacity

- High production capacity for large-format cutting

- Feature

- High precision, robust structure, stable performance

- Color

- Blue/White

- Exhaust System

- Inbuilt air exhaust fan and air assist pump

- Laser Wavelength

- 10.6 m

- Repeat Positioning

- 0.02 mm

- Laser Tube Lifetime

- 8000-10000 hours

- Interface Type

- USB, Ethernet

- Positioning Accuracy

- 0.05 mm

- Safety Features

- Emergency stop, interlock system, protective cover

- Working Environment

- Temperature 5-40C, Humidity < 95%, non-condensing

- Supported Operating System

- Windows XP/7/8/10

- Max Power Consumption

- 2500W

- Transmission

- Belt drive

- Focusing Mode

- Manual / Automatic (optional)

- Drive Type

- Stepper Motor / Servo Motor (optional)

- Table Type

- Honeycomb and Blade Table

Large Bed Laser Cutting Machine Trade Information

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- Delivery Time

- Week

- Main Export Market(s)

- Asia

- Certifications

- Yes

About Large Bed Laser Cutting Machine

With rich industry and market knowledge, we are affianced in manufacturing and supplying a wide assortment of Large Bed Laser Cutting Machine. This is used for cutting the large workpiece with the help of laser light at various industries like metalworking, woodworking, textile, ceramic etc. It is manufactured using premium quality components and cutting edge technology by our dedicated professionals. Furthermore, the offered Large Bed Laser Cutting Machine can be purchased from us at reasonable prices.

Key points:

Key points:

- High strength

- Longer working life

- Easy operations

- Simple to operate

High Precision Meets Versatility

Designed for industrial-grade cutting tasks, this laser cutting machine features a DSP control system and both manual and automatic focusing modes. The combination of 0.05 mm positioning accuracy and various table types enables precise and clean cuts every time, making it ideal for sign making, template processing, and furniture manufacturing.

Optimized for Large-Format Production

With its expansive 1300 mm x 2500 mm working area and high-speed capabilities up to 600 mm/s, the machine accommodates substantial materials and high production volumes. The rugged construction and high production capacity ensure stable, reliable operation for demanding applications.

Safety and User Convenience

This cutter is outfitted with essential safety measures including an emergency stop, interlock system, and protective cover. The built-in exhaust fan and air assist pump, coupled with water cooling, improve operational safety and performance while minimizing downtime and maintenance requirements.

FAQs of Large Bed Laser Cutting Machine:

Q: How does the Large Bed Laser Cutting Machine achieve high positioning accuracy?

A: The machine uses a combination of advanced DSP control systems, precision belt drive transmission, and stepper or servo motors. These components work together to ensure positioning accuracy of 0.05 mm and repeat positioning accuracy of 0.02 mm, ideal for demanding cutting applications.Q: What materials can be processed with this laser cutting machine?

A: This CO2 laser cutter is designed for non-metal materials such as acrylic, MDF, wood, leather, fabric, paper, and plastic. Its widely used in industries like sign making, furniture manufacturing, template processing, and advertising.Q: How does the focusing mode work and which options are available?

A: Focusing can be adjusted either manually by the operator or automatically if equipped with the optional auto-focus function. Automatic focusing uses sensor feedback to ensure precise focal distance, improving efficiency and cut quality across varying material thicknesses.Q: When should I perform maintenance on the laser tube or cooling system?

A: Regular maintenance is essential. The CO2 laser tube typically lasts between 8,000 to 10,000 hours. Its advisable to routinely inspect the water cooling system and replace coolant as needed to prevent overheating and maintain consistent cutting performance.Q: Where can the Large Bed Laser Cutting Machine be installed for optimal operation?

A: This machine performs best in environments with temperatures between 540C and humidity below 95% (non-condensing). Ensure proper ventilation and access to required electrical outlets (220V/380V, single or three phase) to maintain safety and efficiency.Q: What process does the machine use to remove smoke and debris during operation?

A: An inbuilt air exhaust fan and air assist pump are integrated to extract smoke and particles generated during cutting. These systems help keep the workspace clean, protect sensitive components, and enhance laser cutting quality.Q: What are the primary benefits of using this laser cutter for industrial applications?

A: The primary advantages include high production capacity, exceptional precision, flexibility in material handling, stable performance, and robust safety features. Its large-format cutting area accommodates substantial workpieces, making it ideal for various large-scale industrial cutting needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Laser Cutting Machines Category

CO2 Galvohead Laser Machine

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Acrylic, Leather, Wood, Fabric, Plastics, Rubber, Paper, Glass, Ceramics

Laser Type : Other, CO2 Galvohead Laser

Control System : Other, Computerized Control System

Working Area : 150 x 150 mm (custom options available)

High Speed Laser Cutting Machine

Material : Other, Stainless Steel, Carbon Steel, Aluminum, Copper, Brass, Other Metals

Laser Type : Fiber Laser

Control System : Other, CNC Controller

Working Area : 1500 mm x 3000 mm

"We mainly invite inquiries from North India."

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry